R. Sainju, M. Patino, M. J. Baldwin, O. E. Atwani, R. Kolasinski, Y. Zhu* ,Acta Materiala, 278, 2024, 120282

Highlights:

- Tungsten plasma-facing materials are susceptible to high-temperature oxidation during air-ingress fusion reactor accidents, but there's a lack of oxidation kinetic data for irradiated tungsten.

- We utilized atmospheric ETEM to present the first kinetic data for substrate-free W nanofuzz oxidation at 400 °C and 500 °C in 1 bar dry air.

- Time-resolved in-situ characterization reveals a durable amorphous surface oxide, likely promoted by high-flux He+ irradiation-induced surface defects, serving as an effective passivating layer that impedes nanofuzz oxidation onset.

- This new finding challenges conventional notions of irradiation's negative impact on metal oxidation.

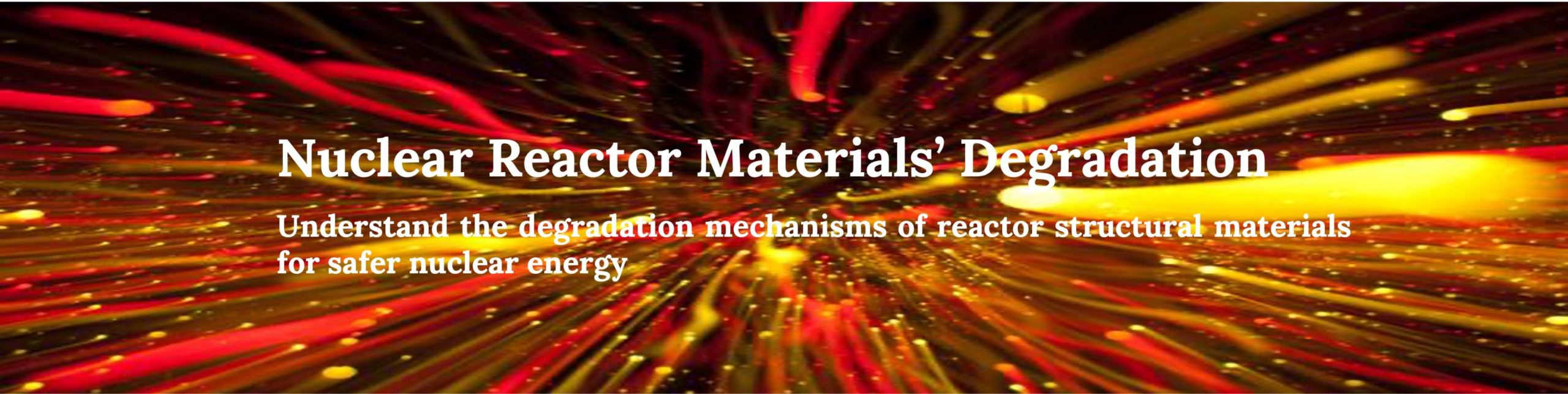

Dose rate effects on damage accumulation and void growth in self-ion irradiated tungsten.

W. Jiang*, Y. Zhu, L. Zhang, D. J. Edwards, N. R. Overman, G. Nandipati, W. Setyawan, C. H. Henager Jr., R. J. Kurtz, Journal of Nuclear Materials, 550, 2021, 152905

Highlights:

- The primary objective of this study is to investigate the dose rate effects on the damage accumulation and void growth in pure W, a major candidate material for the first-wall components of future fusion energy systems

- RBS/C spectra do not show damage peaks, providing direct evidence that SIAs are extremely mobile during irradiation at 300 K and higher

- The damage level at 162 nm (depth of damage peak from SRIM simulations) in mono-W irradiated with self-ions to 1 dpa at 900 K is 0.19% and 1.1% at 10−4 and 10−3 dpa/s, i.e., an increase in the damage level by ~6 times due to dose rate effects

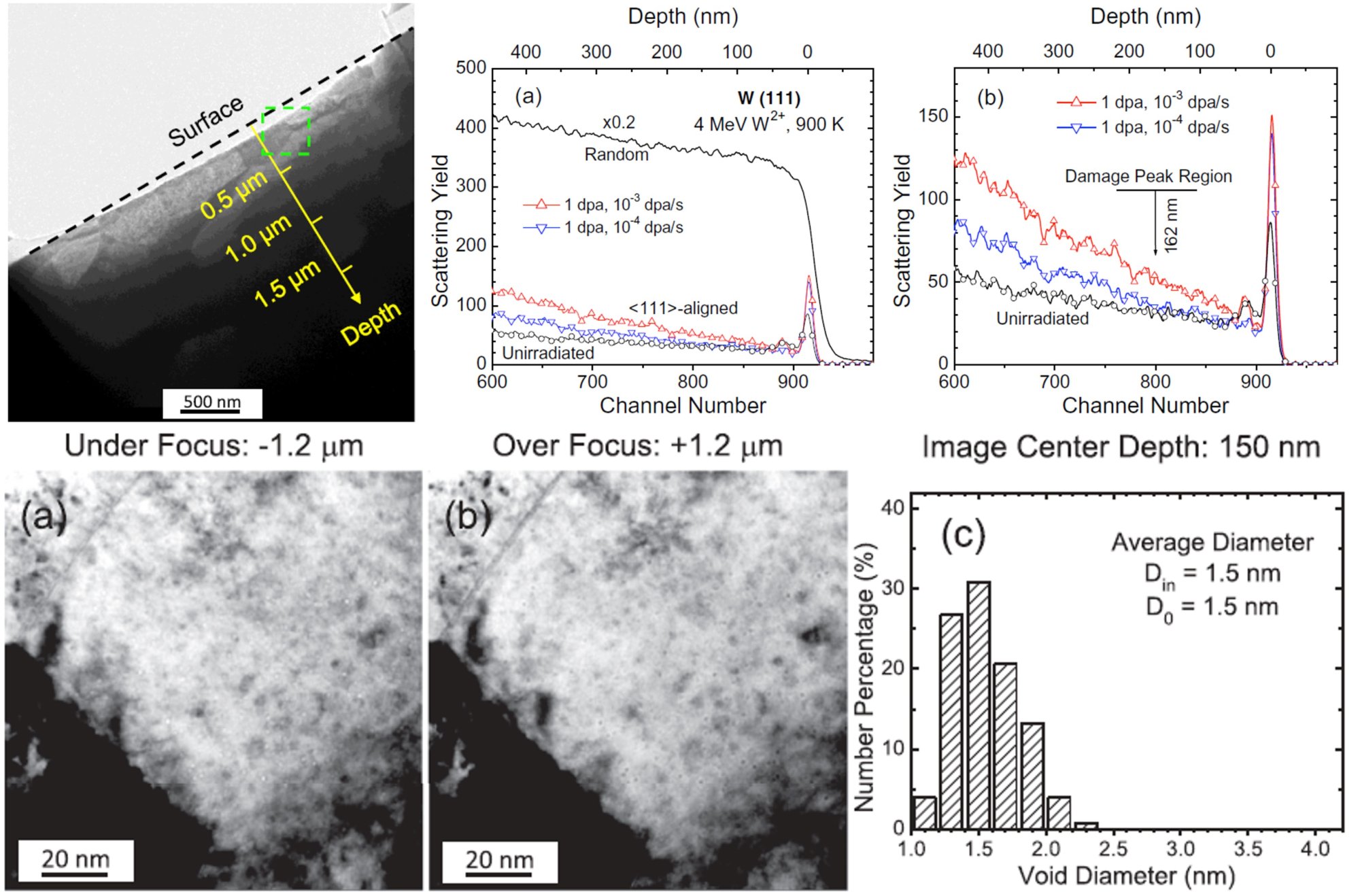

Direct observation of tungsten oxidation studied by in situ environmental TEM. Invited paper to the special issue, "Characterization of Advanced Nuclear Materials under Extreme Environments"

M. Togaru, R. Sainju, L. Zhang, W. Jiang, Y. Zhu*, Materials Characterization, 174, 2021, 111016

Highlights:

- In situ ETEM is a promising new characterization technique that is capable of driving and tracking the dynamic evolution of W PFM under fusion-relevant oxidation conditions

- In situ ETEM reveals the oxide/metal heterointerface moving downwards, agreeing with the Wagner’s diffusion model where the metal oxidation rate is controlled by the inward diffusion of O2- through ‘short-circuit’ diffusion paths such as GBs and dislocation in the tungsten oxide layer

- Tungsten oxides are highly sensitive to tungsten surface orientation and they change dynamically in the course of oxidation

- The discovery of a textured columnar-grained W oxide suggests the existence of inherently high oxidation resistance in certain W surface crystallographic orientations

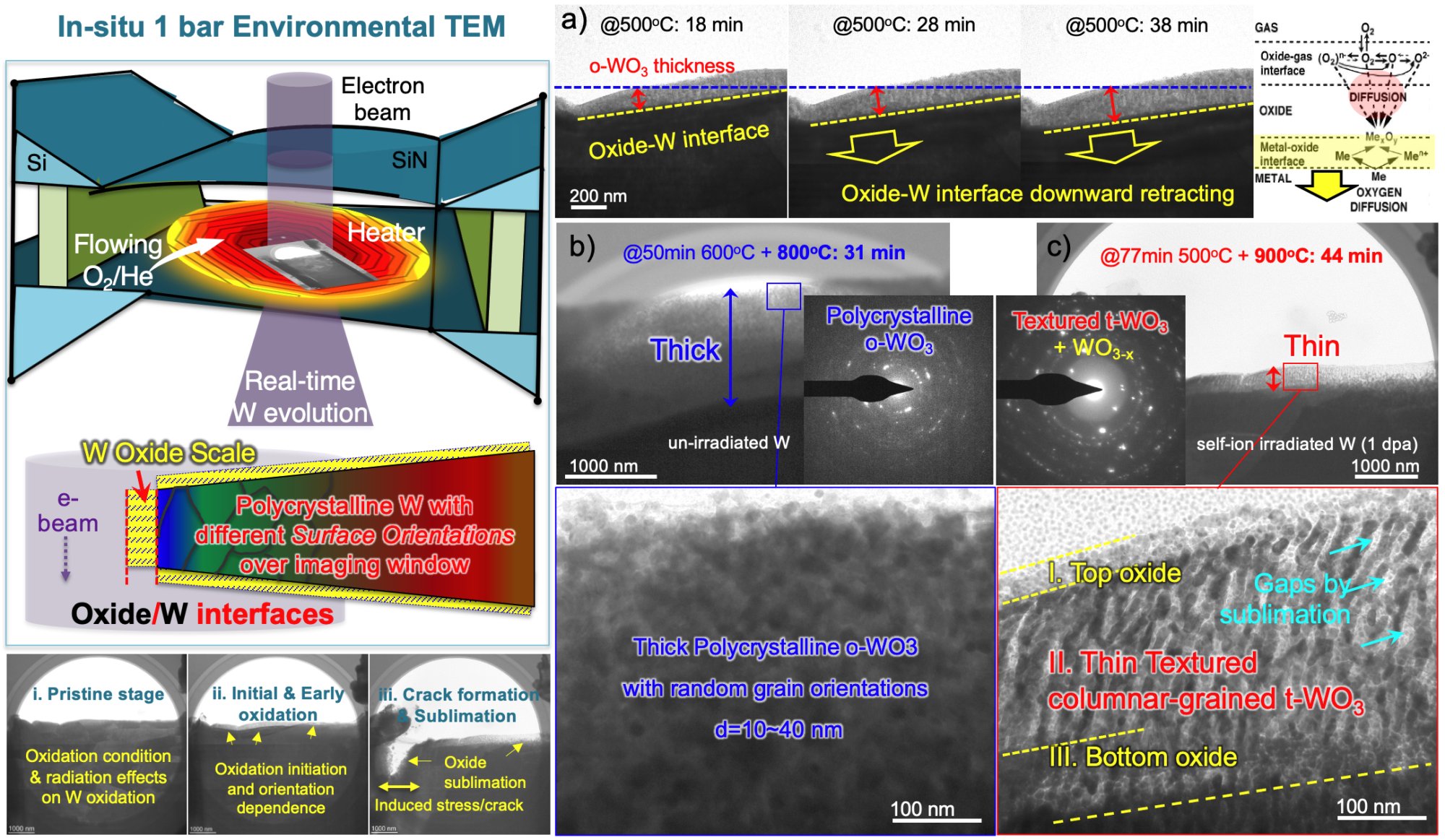

W. S. Cunningham, K. Hattar, Y. Zhu, D. J. Edwards, J. R. Trelewicz*, R. J. Kurtz, Acta Materialia, 206, 2021, 116629

Highlights:

- Grain boundary and associated defect evolution under heavy ion irradiation were explored in Ti-doped nanocrystalline W via correlative TEM/DCI STEM imaging and PED analysis across a wide dose range up to 400 dpa

- Microstructural evolution is modeled in the context of cascade-induced thermal spikes and reveals that the W-20 at.% Ti alloy evolves to a much finer nanocrystalline grain size, indicative of Ti stabilizing the nanostructure against irradiation-induced grain growth

- In situ tracking of defect evolution during the growth of a single grain confirmed the correlation between the transient defect density trends and grain size in the absence of changes to the texture and/or phase distribution

R. Sainju, W. Y. Chen, S. Schaefer, G. Roberts, M. B. Toloczko, R. J. Kurtz, C. H. Henager, D. J. Edwards, M. Li, Y. Zhu*, Microscopy and Microanalysis, 2021, 27 (S1), 1464-1465.

Highlights:

- Advanced in situ TEM equipped with high-energy ion sources are beginning to produce an ‘avalanche’ of big data, e.g. gigabytes of in situ TEM videos produced in a single irradiation experiment, making it increasingly difficult to extract and quantify the temporal information of radiation defect dynamics

- Our computer vision model DefectSegNet and associated MATLAB algorithms perform irradiation defect quantification in HT-9 in a more reproducible and reliable manner in just a few seconds

- Our new multiple object tracking (MOT) computer vision model tracks and quantifies individual defect clusters in Ni irradiated with 1 MeV Kr ions at ANL IVEM in real-time, advancing our understanding of the dynamic evolution of cascade-induced defect clusters

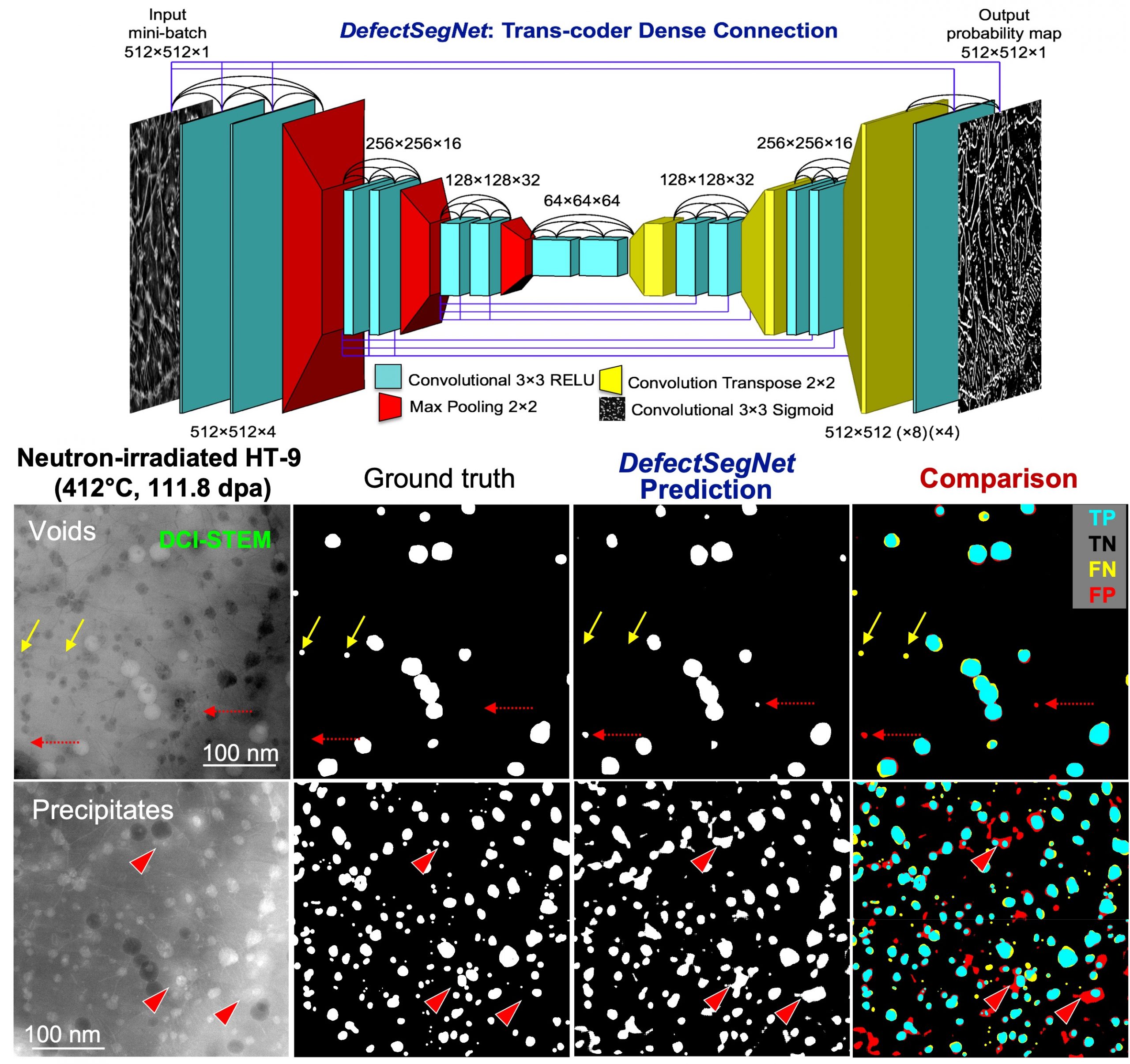

Deep Learning for Semantic Segmentation of Defects in Advanced STEM Images of Steels. Highlighted on the DOE Fusion Energy Sciences (FES) website: AI Helps Scientists Quantify Irradiation Effects

G. Roberts, S. Y. Haile, R. Sainju, D. J. Edwards, B. Hutchinson, Y. Zhu*, Scientific Reports, 9, 2019, 1-12

Highlights:

- We demonstrate the feasibility of automated identification of common crystallographic defects (including extended radiation defects) in HT-9 martensitic steel using deep learning semantic segmentation, based on high-quality microscopy data

- DefectSegNet – a new hybrid CNN architecture with skip connections within and across the encoder and decoder was developed and has proved to be effective at perceptual defect identification with high pixel-wise accuracy

- Deep-learning semantic segmentation established on advanced microscopy and on optimized CNN architecture offers a path forward to the high-throughput defects quantification needed for rational reactor alloy design

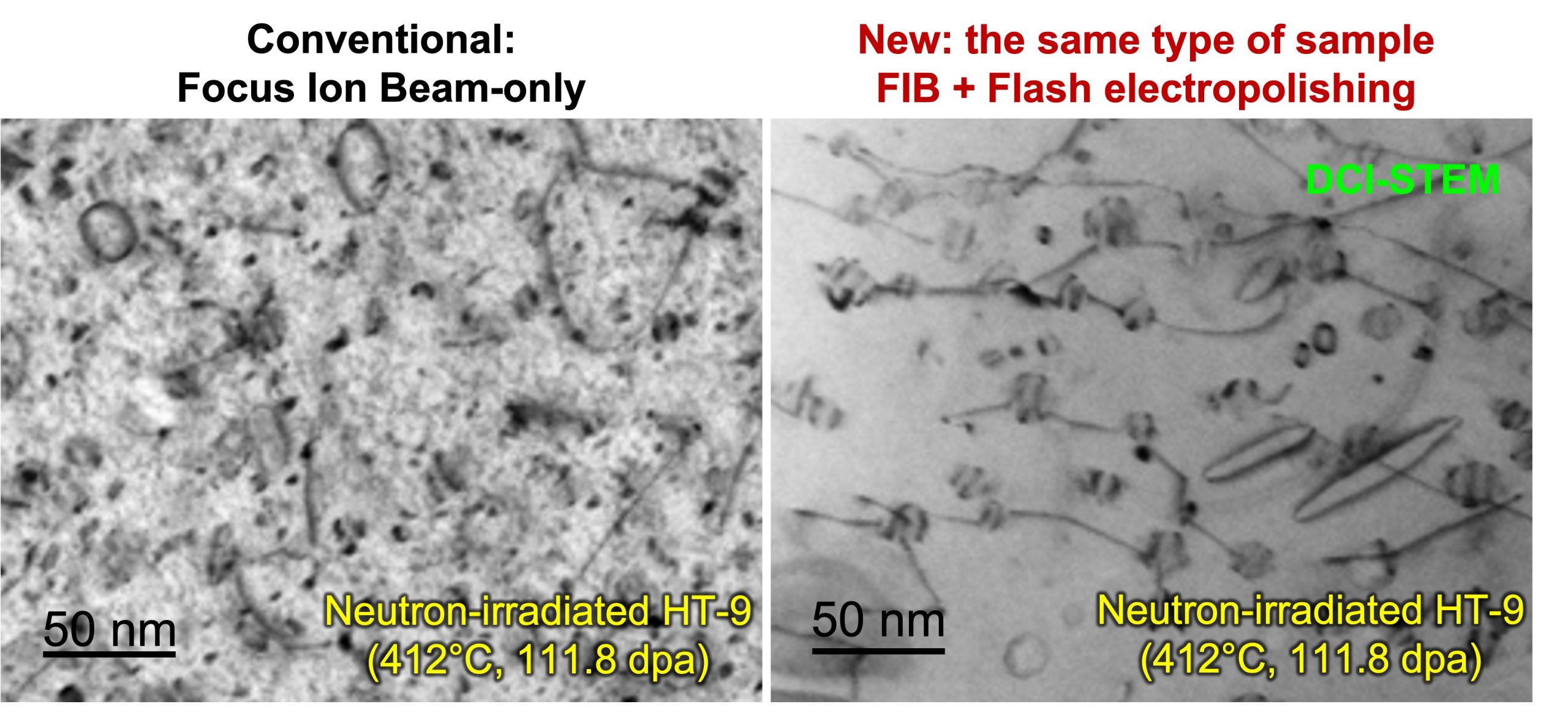

Removal of FIB Damage using Flash Electropolishing for Artifact-free TEM Foils.

A. Schemer-Kohrn, M. B. Toloczko, Y. Zhu, J. Wang, D. J. Edwards, Microscopy and Microanalysis, 2019, 25 (S2), 1606-1607.

Highlights:

- Conventional FIB milling produces a high density of small defect clusters and dislocation loops up to few nanometers in size in TEM foils, obscuring the real radiation defect structure produced during neutron and/or ion irradiation

- We utilize flash electropolishing and successfully produce FIB lamella from HT-9 that is completely free of both the small “black spot” damage and FIB milling induced dislocation loops, as well as the restructured sample surface

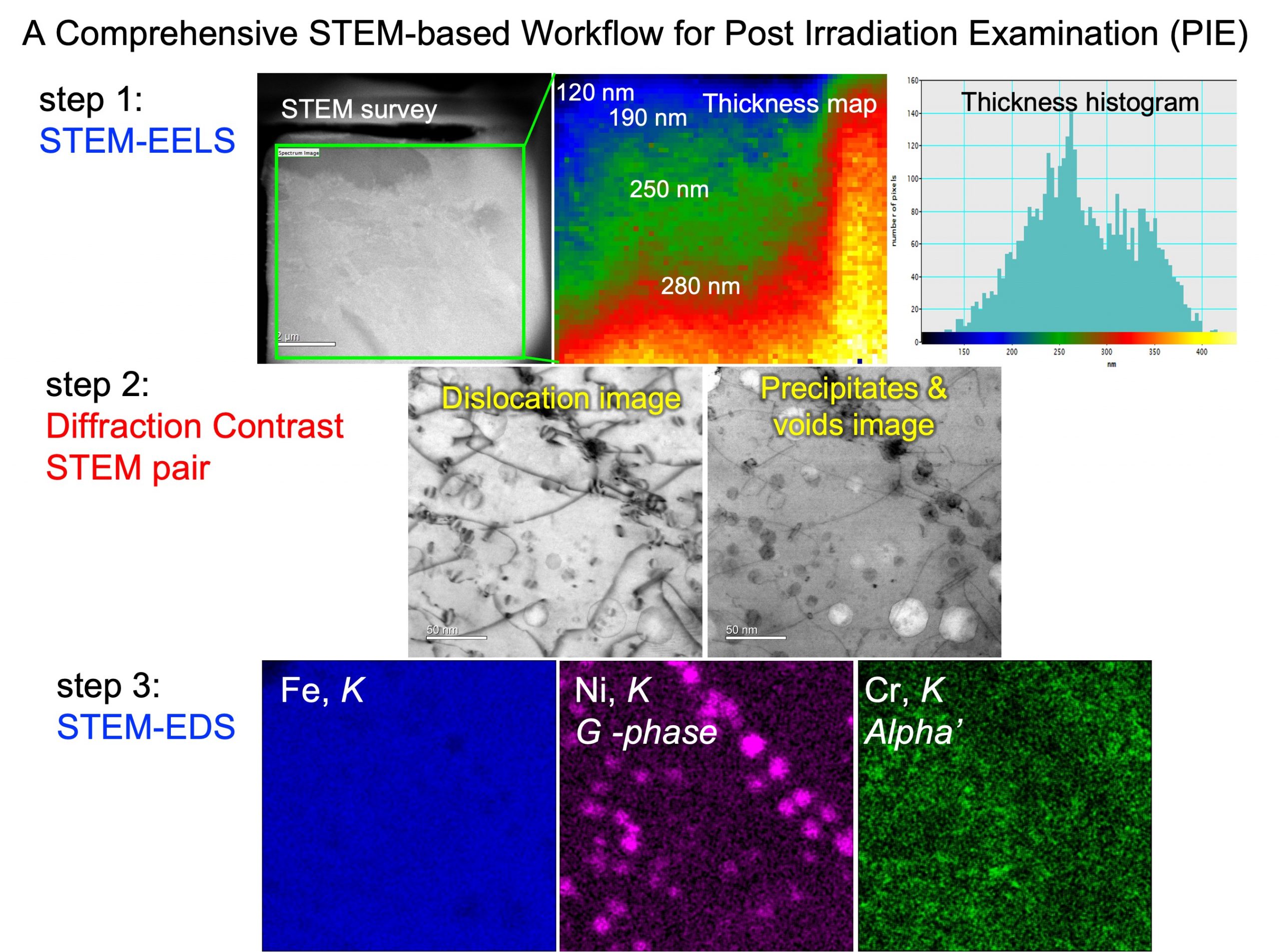

Y. Zhu*, C. Ophus, M. B. Toloczko, D. J. Edwards, Microscopy and Microanalysis. 2018, 24 (S1), 1472-1473.

Highlights:

- Studying radiation effects on the microstructural and mechanical properties of structural materials used for nuclear reactor core components is critical for clean and safe implementation of nuclear energy

- Combine the Diffraction Contrast STEM imaging with STEM-EELS and STEM-EDS, we propose a workflow for comprehensive microstructural and chemical characterization of irradiation effects

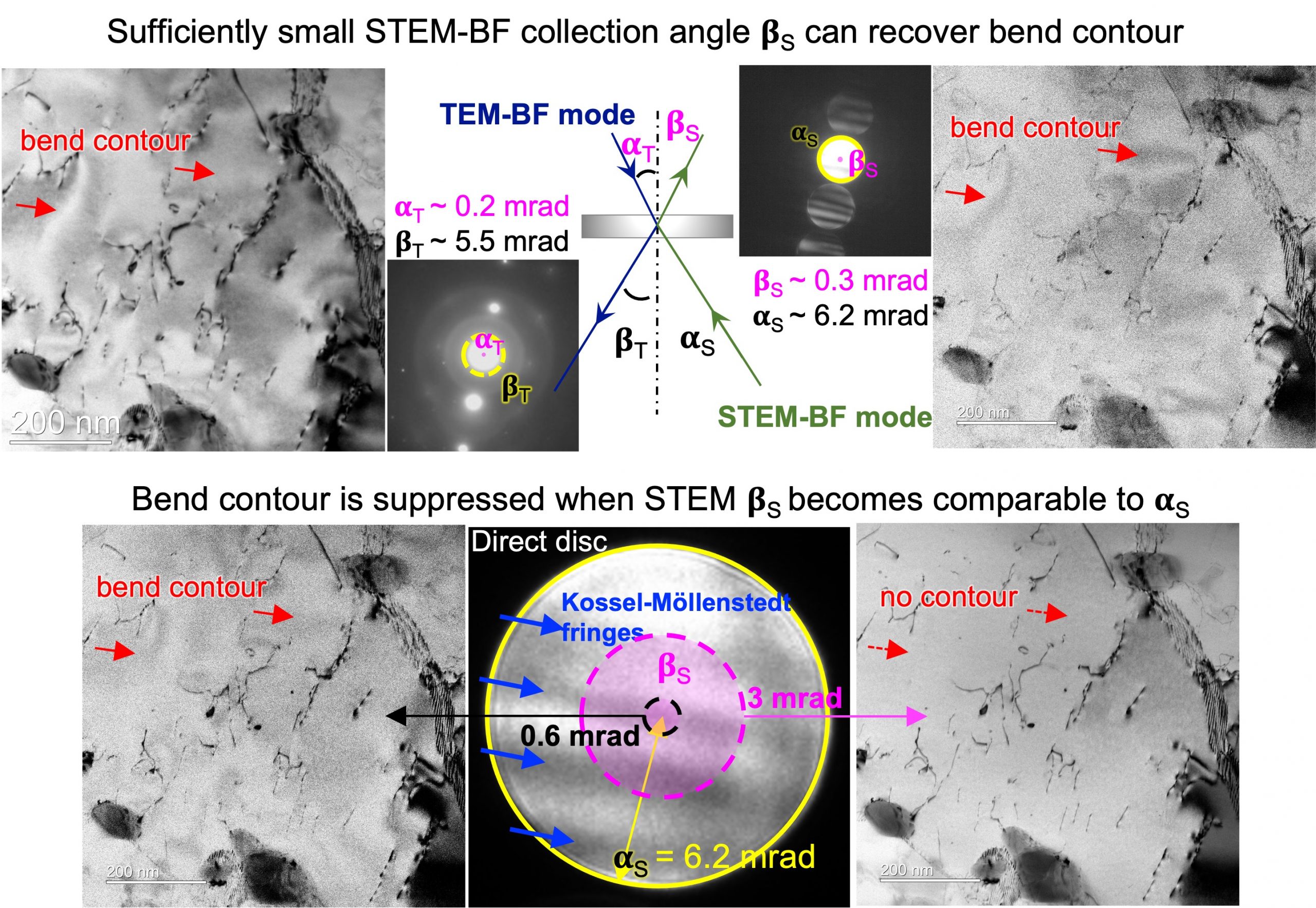

Towards bend-contour-free dislocation imaging via diffraction contrast STEM

Y. Zhu*, C. Ophus, M. B. Toloczko, D. J. Edwards, Ultramicroscopy, 2018

Highlights:

- Full explanations on why diffraction contrast STEM reduces bend contour artifacts

- Outline the setup of diffraction contrast STEM dislocation imaging

- Guidelines for the optimization of diffraction contrast STEM dislocation imaging

- A comprehensive structural and chemical characterization is established in STEM mode